Prepreg carbon fiber material from Toray is used instead of the more traditional wet lay-up carbon fiber. Kevlar is also lighter weight than steel. It is as strong as steel push-rods in tension.

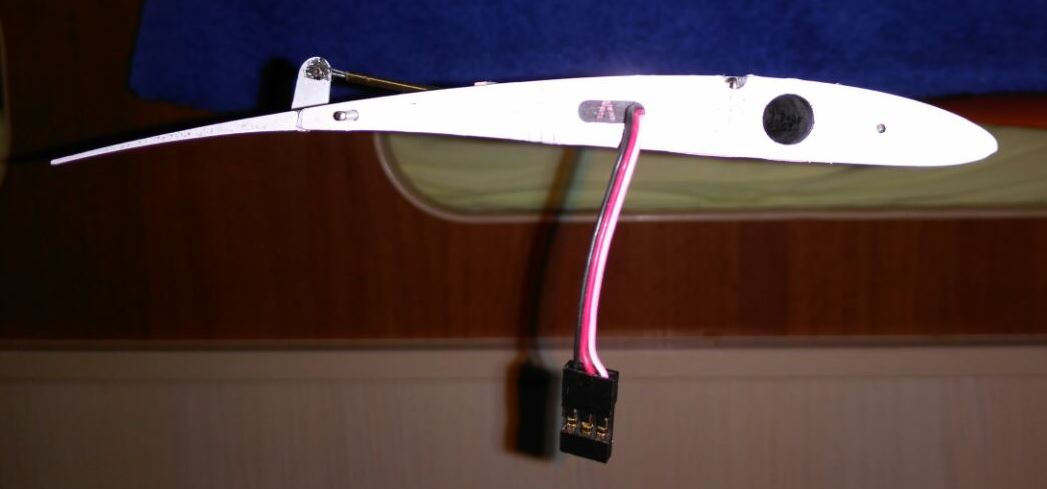

Wade: Kevlar-based cable is used instead of the more traditional steel push-rods for the aileron, rudder and elevator. Question: What are some of the less conventional materials that are being used in the gliders? Lighter weight gliders are less expensive to build.The lift is easier to work and therefore it ia easier to gain altitude. It has a low sink rate and low wing loading so it can efficiently climb in weak lift (aka.Unlike conventional gliders that require 2 or more people to assemble or require special rigs, these gliders have light wings and can be assembled with one person. Question: What are the advantages to an ultra light weight glider? (For comparison, the Glasflügel 303 Mosquito glider has an empty weight of 532lbs.) and the DuckHawk SV with an empty weight of 435lbs. Wade: Greg Cole, the owner and chief designer, wanted to create an ultra-light sailplane that is fun and safe to fly.Ĭurrent models include the SparrowHawk which has an empty weight of 154lbs. Question: What was the inspiration to starting Windward Performance? I had a chance to talk with Wade Carman, an engineer and glider pilot at Windward Performance, about the innovative gliders that they they are developing.

Using less conventional materials and new airfoil designs, the company is creating gliders with improved performance when compared to its competitors. have caused a buzz in the glider community. The gliders produced by Windward Performance LTD.

0 kommentar(er)

0 kommentar(er)